Cognitive Services

Industrial AI Solutions

Benefits offered by byteLAKE’s Cognitive Services

- Accelerate Data Analytics

Processing data from various sources, including images, videos, and sensors. - Automate Quality Inspection

Ensuring high accuracy in inspecting products and processes.

Eliminating potential human errors for consistent and reliable results.

Increasing overall quality and reliability. - Optimize Operations and Maintenance

Reducing unnecessary inspections and lowering maintenance costs.

Predicting potential failures and downtimes. - Continuous Monitoring

Offering 24/7/365 monitoring without boredom or distraction.

Offloading and supporting human operators. - Easy Replication

Enabling quick deployment.

Functioning offline without an internet connection. - Continuous Improvement

The solution can learn and improve over time.

AI in Manufacturing – benefits

- Enhanced Productivity

Streamlining processes for increased productivity.

Efficient resource allocation based on real-time data.

- Customization and Adaptability

Tailoring AI models to specific manufacturing requirements.

Adapting to changing production needs seamlessly.

- Reduced Downtime

Minimizing production downtime through predictive maintenance.

Optimizing machine uptime and reliability.

- Data-Driven Decision-Making

Empowering decision-makers with actionable insights.

Enabling data-driven strategies for process improvement.

- Consistent Quality Control Across the Organization

Ensuring consistent product quality throughout the production process.

Meeting industry standards and regulations effortlessly.

Data Insights

Analyze trends, patterns, predict maintenance needs,

identify root causes of errors,

and suggest optimal energy-saving settings.

Quality Inspection

AI-driven automated inspection and quality control processes

ensure products meet rigorous quality standards.

Visual Inspection

Identify faulty elements, count objects, and diagnose equipment

or product issues from images or videos.

Sound Analytics

Identify faulty elements and diagnose equipment

or product issues from sound patterns.

Papermaking Monitoring

AI detects and analyzes the wet line to optimize production,

reduce waste, and enhance efficiency.

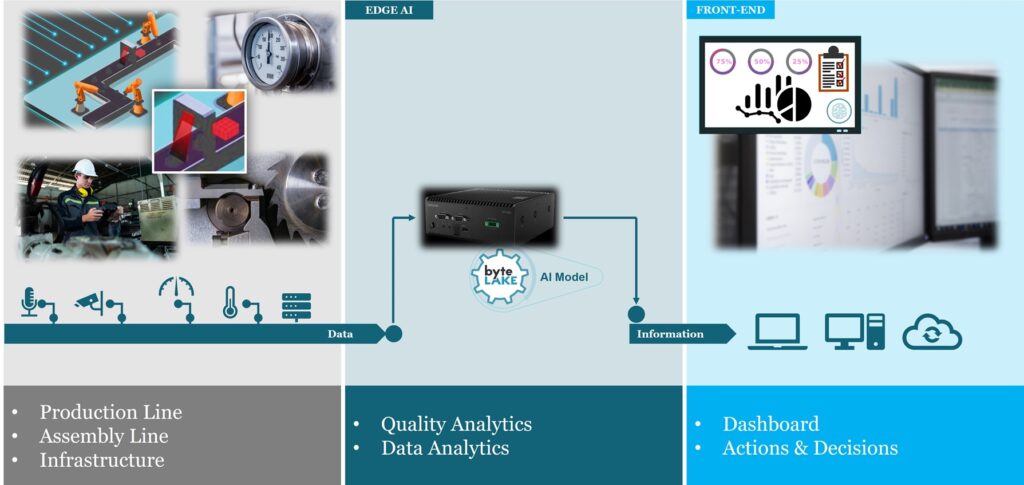

Example Deployment

How to Start

- Define the Scenario

- Determine the purpose of AI analytics, such as detecting surface anomalies, monitoring assembly lines, automating operations, accelerating processes (e.g., production, purchasing), automating repetitive and dangerous tasks, improving analytics for better decision-making, and enabling predictive maintenance. Are there any other specific objectives?

- Explain Expectations

- Discuss the placement and quantity of cameras or sensors to be used if known.

- Describe existing and potential data sources, including future ones if known.

- Specify the desired level of accuracy.

- Provide information about production rates and expected system performance, considering future growth.

- Define uptime requirements and any other specific system requirements.

Licensing & Cost of Deployment

- Licensing

Annual/monthly licensing plans for Cognitive Services, including upgrades, customer care, and support. - AI Model Development

Costs for AI model training and calibration. - Data Management

Expenses related to data collection and cleaning. - Hardware and Software (if needed)

Hardware costs, as well as any associated licenses.

Installation expenses. - Integration and Deployment

Integration efforts as required for successful deployment.

Contact CognitiveServices@byteLAKE.com to learn more.

Downloads:

Cognitive Services for Industries (tech brief)

AI-assisted Visual Inspections and Faster Data Analytics (Solution Brief)

Cognitive Services for Industries (brochure)

Benchmarks:

Performance benchmark (Intel® CPUs & GPUs 2024)

(soon)

Cognitive Services (max performance with Intel® CPUs)

Cognitive Services (max performance with OpenVINO™)

Follow this project:

AI for Industries

(blog post series)