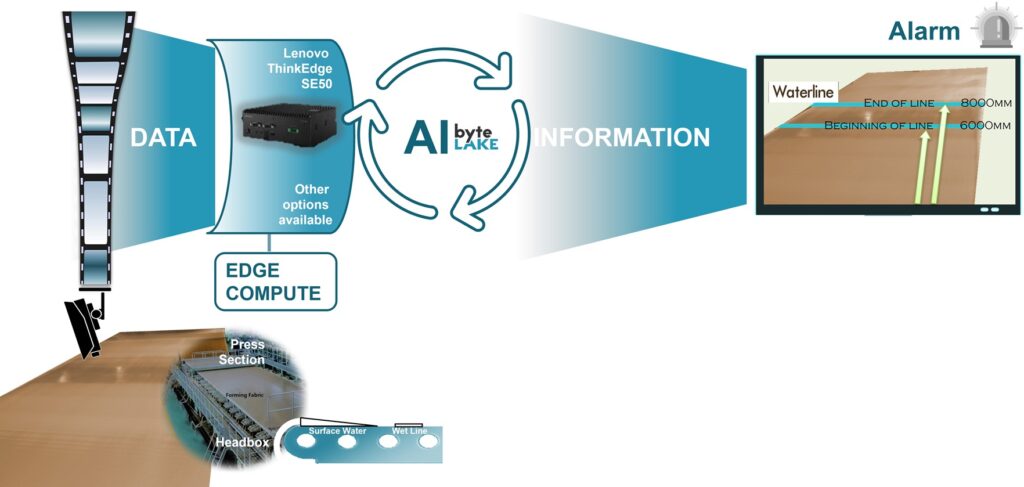

Papermaking Monitoring

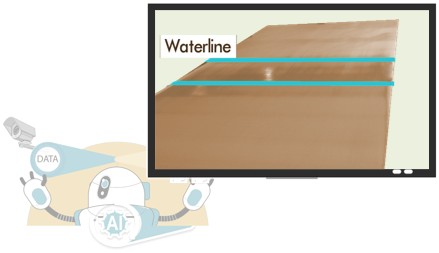

Implement advanced cameras to continuously monitor the papermaking process, accurately detecting and analyzing the wet line. Optimize production, reduce waste, and enhance efficiency.

Detect, measure, and analyze wet line

- Continuous monitoring, 24/7/365

Key Features & Benefits

- Visual Inspection

Continuous process monitoring for quality assurance. - Data Insights

Facilitating predictive maintenance to prevent unexpected downtimes.

Identifying and mitigating risks proactively.

Optimizing manufacturing operations through data-driven insights.

Discovering dependencies within your production processes. - High-Quality Standards Assurance

Ensuring adherence to stringent quality standards throughout production. - Real-time Alerts

Providing instant notifications for critical issues, enabling swift action. - Enhanced Efficiency

Streamlining operations and reducing waste through data-driven optimization. - Customization and Scalability

Tailoring AI models to your specific manufacturing needs.

Scaling the solution as your production demands grow.

Visit byteLAKE.com/en/CognitiveServices and contact CognitiveServices@byteLAKE.com to learn more.

- Plan your AI project here.

Image Credit: PIV measurements of flow through forming fabrics : researchgate.net/figure/…

Downloads:

Cognitive Services for Industries (tech brief)

AI-assisted Visual Inspections and Faster Data Analytics (Solution Brief)

Cognitive Services for Industries (brochure)

Wet Line Analytics (whitepaper)

Benchmarks:

Performance benchmark (Intel® CPUs & GPUs 2024)

(soon)

Cognitive Services (max performance with Intel® CPUs)

Cognitive Services (max performance with OpenVINO™)

Follow this project:

AI for Industries

(blog post series)

AI helps paper mills

increase efficiency and lower costs

Paper Mills Press On

With AI Visual Inspection

Wet Line Detector

for Paper Mills

AI-assisted real-time visual monitoring

for paper production (paper industry)