AI-powered Data Insights

Utilizing AI to analyze data and extract valuable insights, facilitating informed decision-making in various industries.

Analyze trends, patterns, predict maintenance needs,

identify root causes of errors, and suggest optimal energy-saving settings.

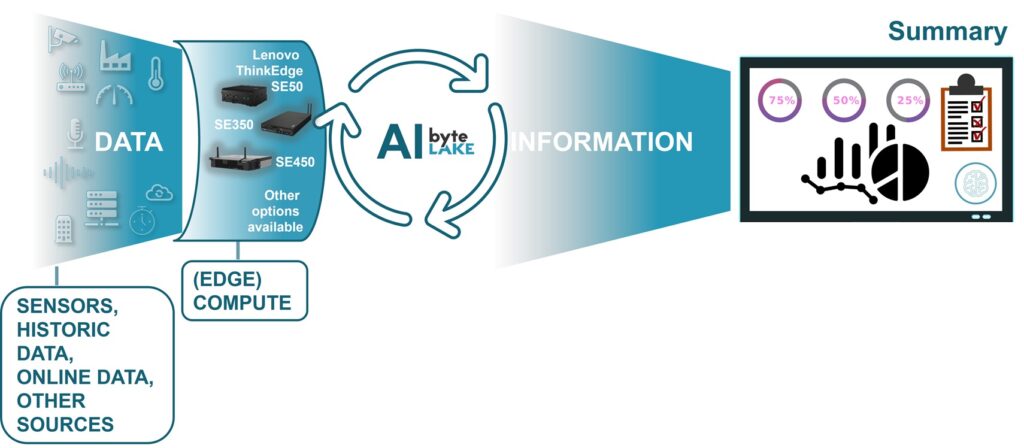

Converting DATA into actionable INSIGHTS

- understand why something happens

- what will likely happen and when?

- find optimal configuration

- explore dependencies

- etc.

Key Features

- Data Insights

Facilitating predictive maintenance to prevent unexpected downtimes.

Identifying and mitigating risks proactively.

Optimizing manufacturing operations through data-driven insights.

Discovering dependencies within your production processes. - High-Quality Standards Assurance

Ensuring adherence to stringent quality standards throughout production. - Real-time Alerts

Providing instant notifications for critical issues, enabling swift action. - Enhanced Efficiency

Streamlining operations and reducing waste through data-driven optimization. - Customization and Scalability

Tailoring AI models to your specific manufacturing needs.

Scaling the solution as your production demands grow.

Benefits

- Accelerate Data Analytics

Processing data from various sources, including images, videos, and sensors. - Automate Quality Inspection

Ensuring high accuracy in inspecting products and processes.

Eliminating potential human errors for consistent and reliable results.

Increasing overall quality and reliability. - Optimize Operations and Maintenance

Reducing unnecessary inspections and lowering maintenance costs.

Predicting potential failures and downtimes. - Continuous Monitoring

Offering 24/7/365 monitoring without boredom or distraction.

Offloading and supporting human operators. - Enhanced Productivity

Streamlining processes for increased productivity.

Efficient resource allocation based on real-time data. - Reduced Downtime

Minimizing production downtime through predictive maintenance.

Optimizing machine uptime and reliability. - Data-Driven Decision-Making

Empowering decision-makers with actionable insights.

Enabling data-driven strategies for process improvement. - Consistent Quality Control Across the Organization

Ensuring consistent product quality throughout the production process.

Meeting industry standards and regulations effortlessly.

Visit byteLAKE.com/en/CognitiveServices and contact CognitiveServices@byteLAKE.com to learn more.

- Plan your AI project here.

Downloads:

Cognitive Services for Industries (tech brief)

AI-assisted Visual Inspections and Faster Data Analytics (Solution Brief)

Cognitive Services for Industries (brochure)

Benchmarks:

Performance benchmark (Intel® CPUs & GPUs 2024)

(soon)

Cognitive Services (max performance with Intel® CPUs)

Cognitive Services (max performance with OpenVINO™)

Follow this project:

AI for Industries

(blog post series)